|

|

|

Promax Imaging offers a range of equipment specifically designed for cleaning inkjet cartridges.

Promax recognises that industrial size equipment is not suitable for use in High Street refilling shops, nor is small equipment suitable for a large factory. Therefore Promax offers equipment to fit the requirements and budgets of both shop based refiller’s and large scale remanufacturer’s.

Small Scale Equipment

ProFill Mini Boiler

click here for more information MiniBoiler

Mini Oven The Mini Oven is in the later stages of development and will be available soon. It will be a small vacuum oven capable of drying the sponges of cartridges thus increasing potential fill volumes and shelf life. Watch this space for updates.

Large Scale Equipment VB120 Vacuum Boiler

click here for more information Vacuum Boiler

VO66 Vacuum Oven

click here for more information Vacuum Oven

Products for all Refiller’s

Spinners

Spins at 2200 rpm

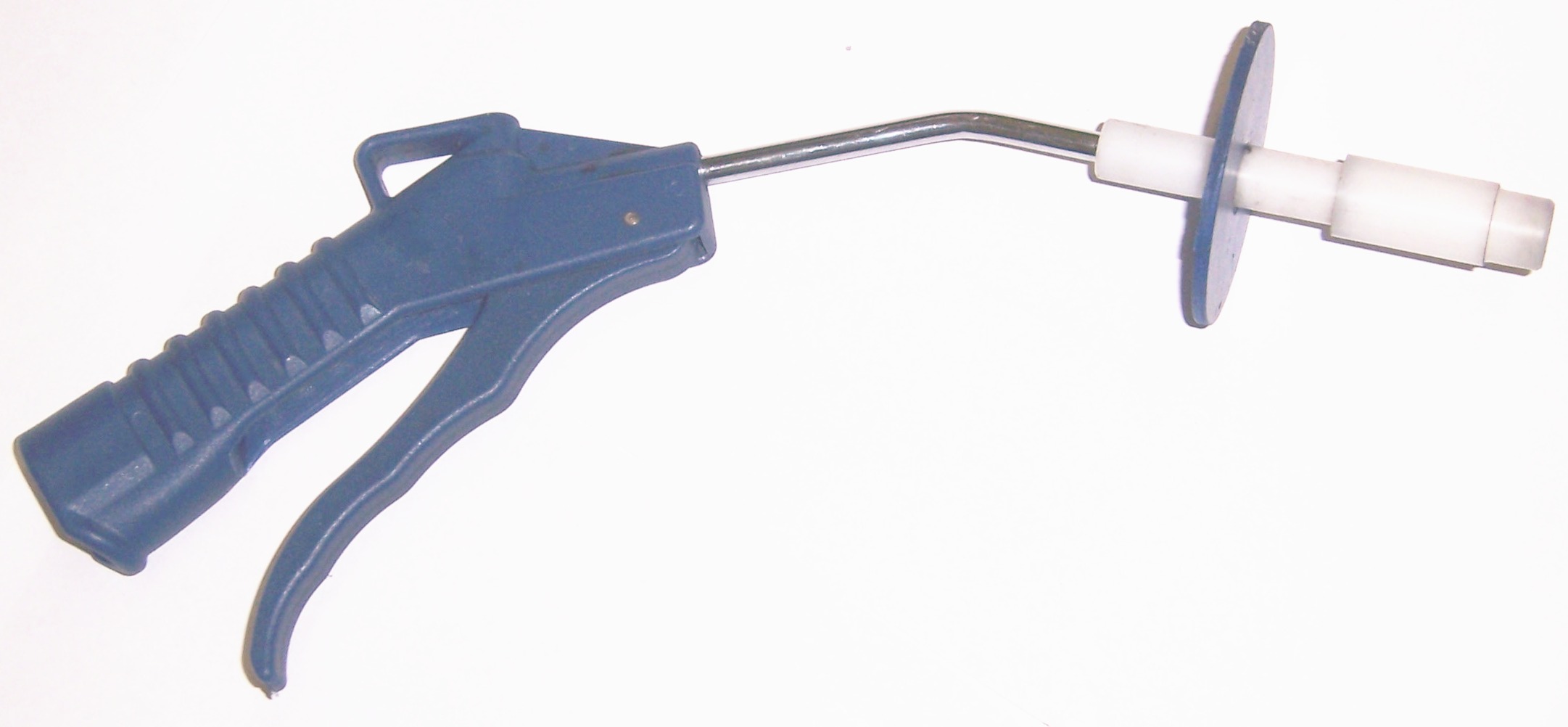

Water Jet Lance

Soak Pan Warmer

click here for more information Soak Pan Warmer |

| [Promax Imaging Ltd] [Equipment] [Cleaning] [Filling] [Testing] [Ink] [Contract Work] |

Ideal tool to clean below the pre firing chamber of Lexmark 10N16 and 1970 style cartridges without removing the filters.

Ideal tool to clean below the pre firing chamber of Lexmark 10N16 and 1970 style cartridges without removing the filters. Soak cartridges in heated cleaning solutions. Especially effective with Promax’s Lexmark Cleaning Solution

Soak cartridges in heated cleaning solutions. Especially effective with Promax’s Lexmark Cleaning Solution